Products

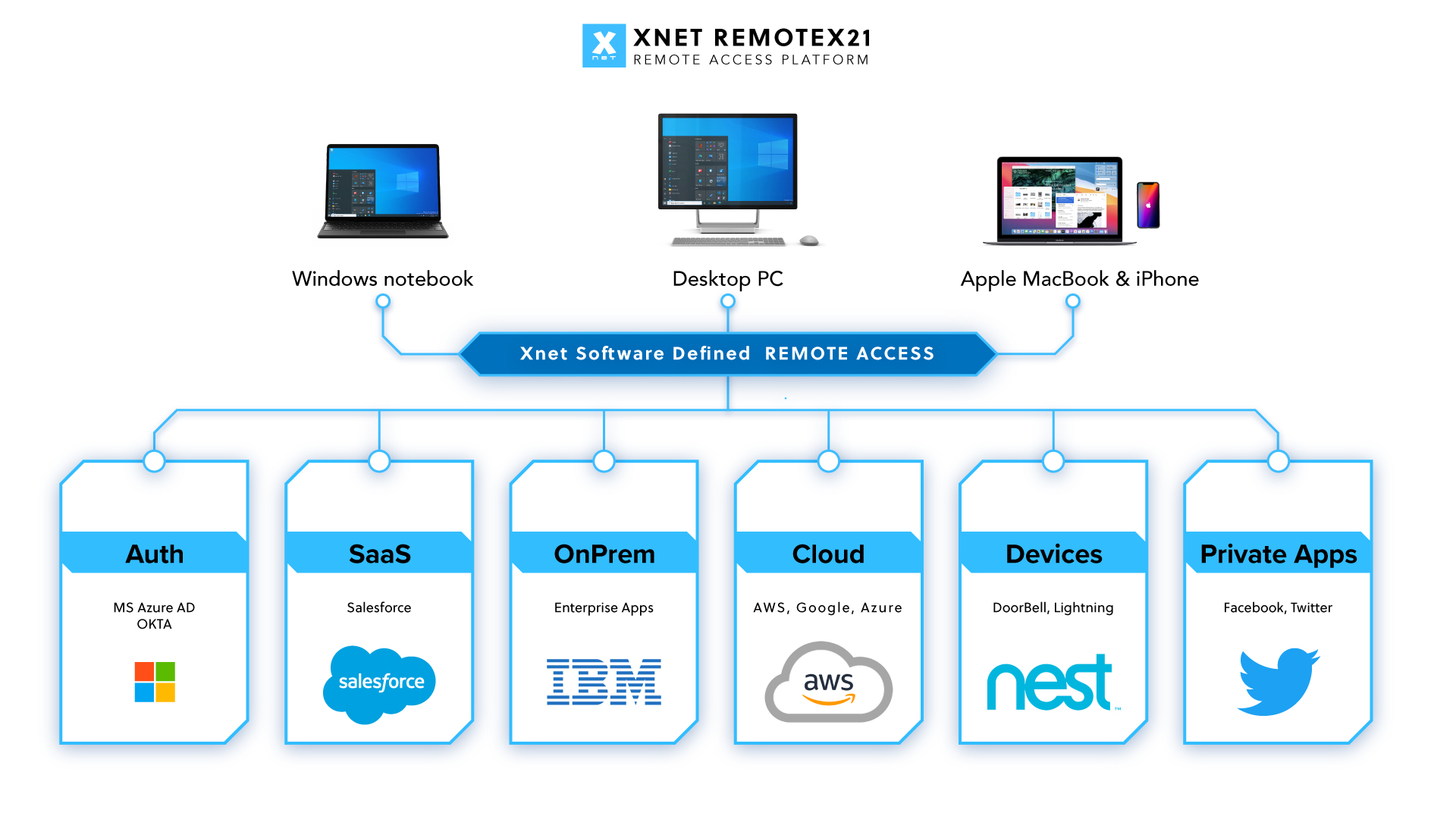

Xnet Secure Gate

Network Security

Digital Network Architecture

Cloud Project Management

Netop Remote Control

Remote Access

Xnet Secure File Transfer

Secured File Transfer

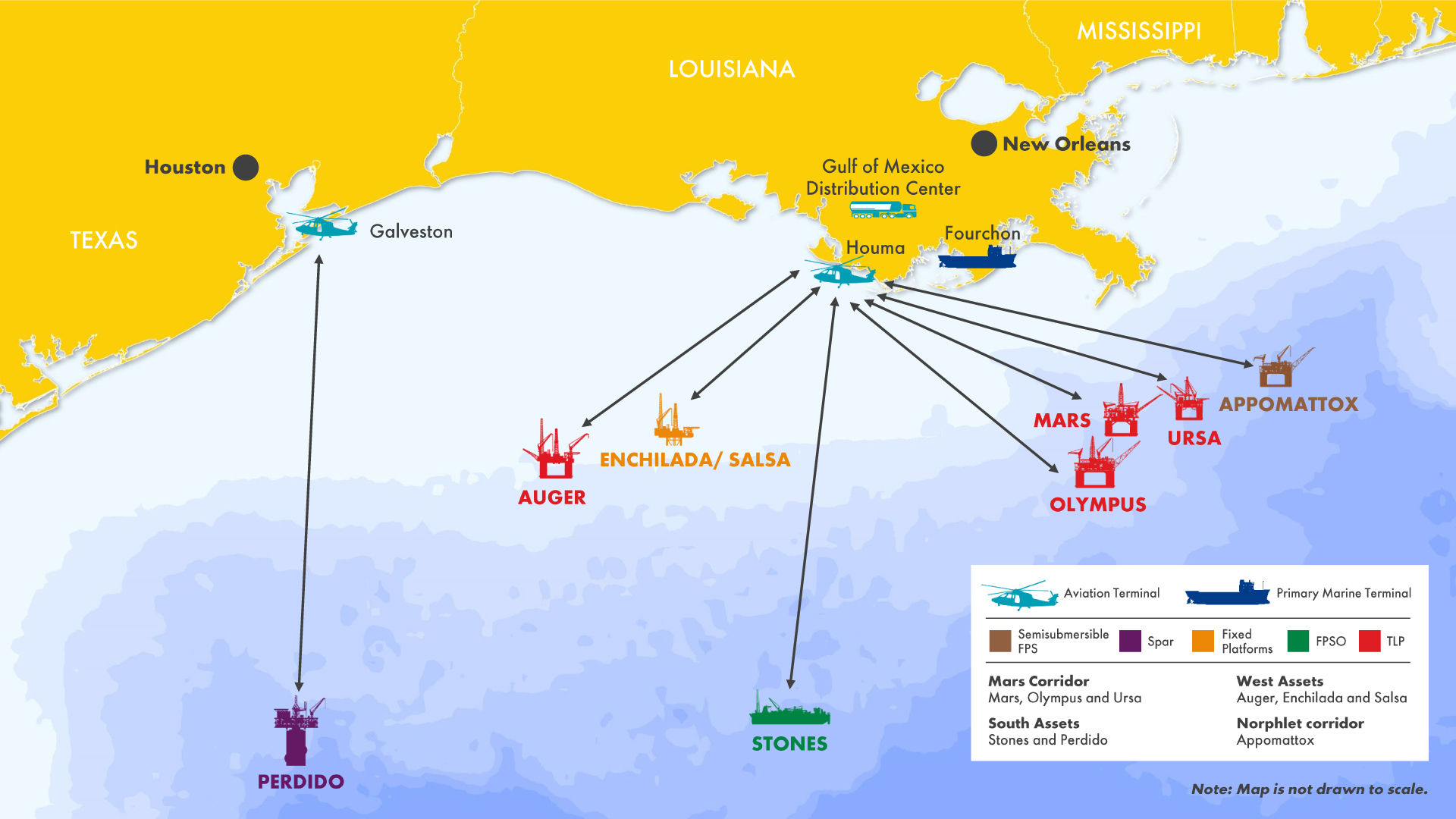

Remote Factory

Secure Industrial Remote Access

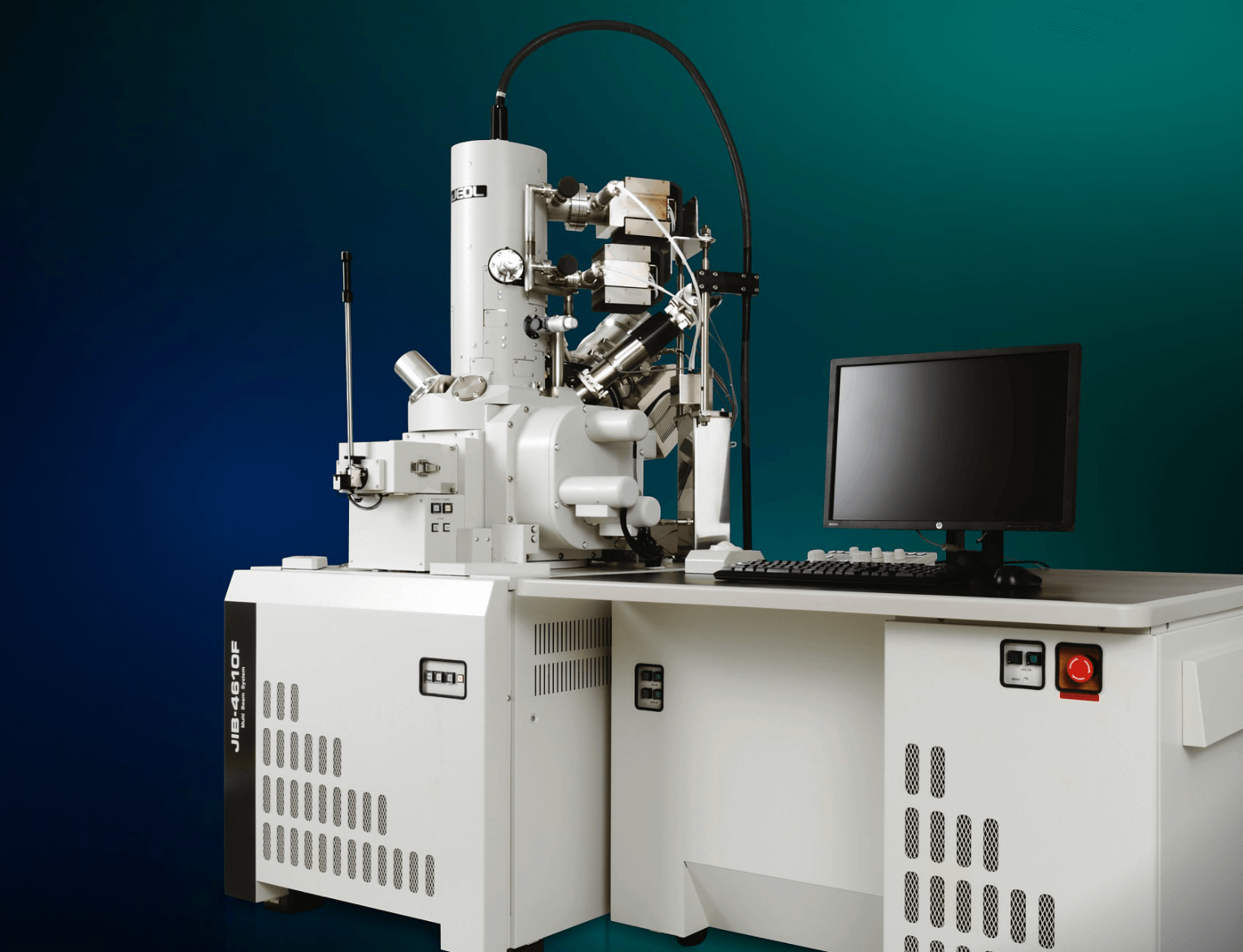

Remote Powertrain

Automotive Engine

Content Menagement

Connect & Manage